Novinka v portfóliu

Dodanie, inštalácia a oživenie Inteligentných skladových systémov a mobilných robotov

Machine Vision | PLC | HMI | Python | Labview

development

This text is set by default and is suitable for edit in real time. By default the drag and drop core feature will allow you to position it anywhere on the site. Get creative, Make Web.

Pod kontrolou

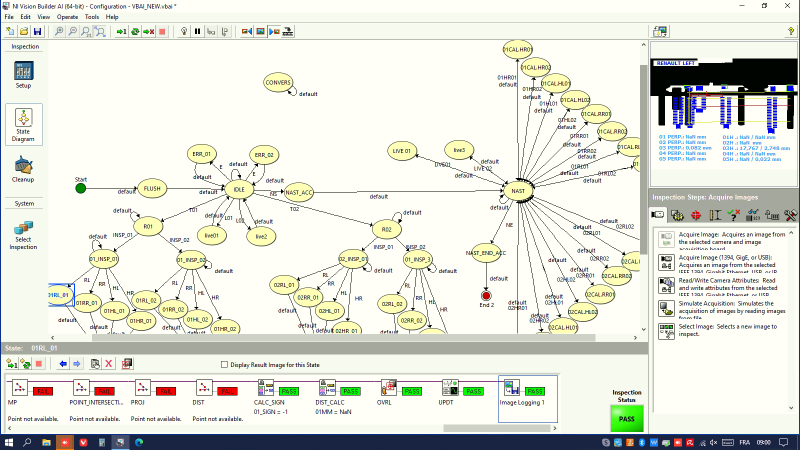

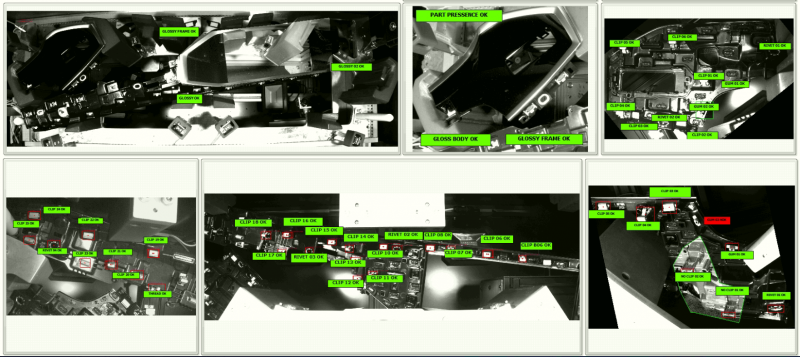

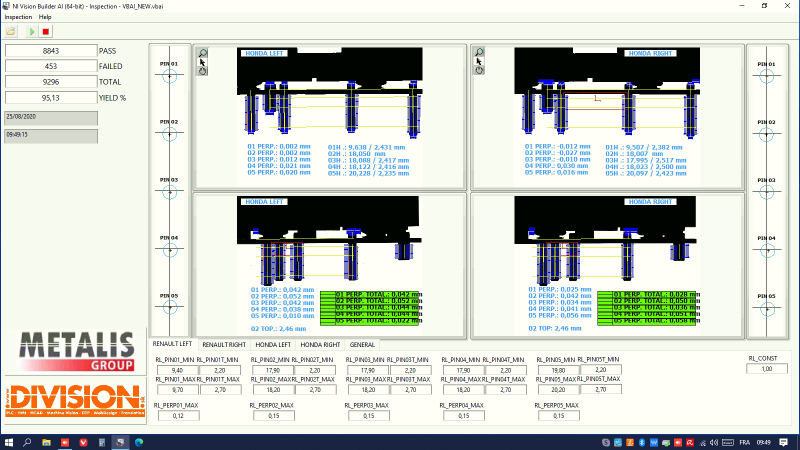

Pre našich klientov vytvárame špecifické Machine Vision aplikácie založené na osvedčenom systéme Vision Builder vytvorené firmou NATIONAL INSTRUMENTS, preslávenou meracím softvérom LabView po celom svete. Či už klient potrebuje jednoduchú aplikáciu, alebo nie vyhovieme každému.

Full control

We develop for our clients specific machine vision application based on reliable Vision Builder software developed by NATIONAL INSTRUMENTS well known around a world for LabView development platform. Simple detection or complicated inspection system, we can provide it all.

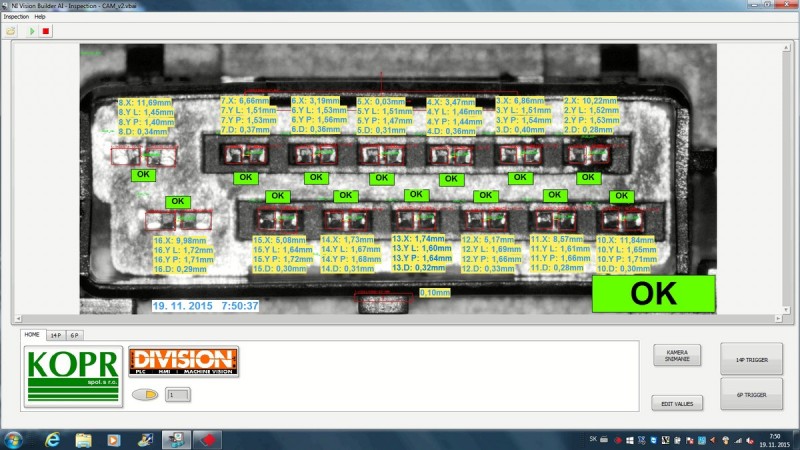

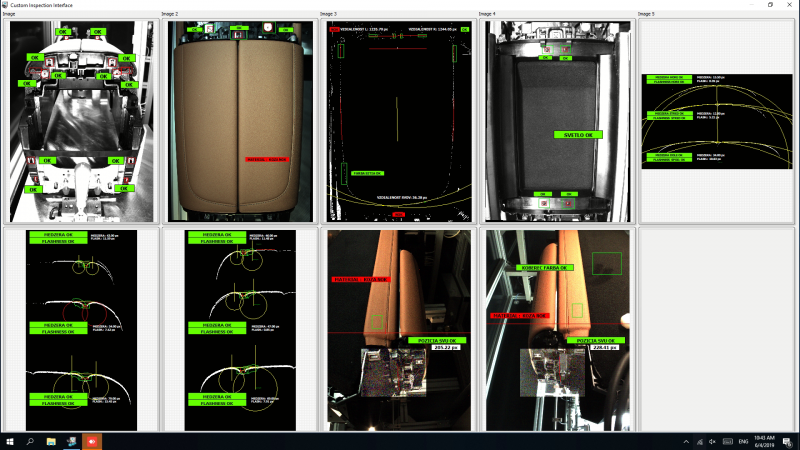

Užívateľské rozhranie

Návrh rozhrania je plne podľa požiadaviek klienta. Ovládacie prvky aj hraničné hodnoty je možné nastaviť aj bez potreby editovať aplikáciu.

User interface

User interface design is fully under client requirements. Control objects and judgement values can be adjusted by client without editing application.

Partneri / Partners